Induction Heating

This simple and cost-effective heating process delivers fast and consistent heat for:

- Welding Fabrication and construction

- Preheating of welds

- Post-weld heat treatment

- Coating removal; and

- Shrink fit applications

Applications that would typically require hours to heat can be done in minutes utilizing induction heating.

Three types of inductors can be connected to the ProHeatpower source

(depend on applications requirements)

- Liquid-cooled heating cable

different lengths (160ft max.) - Induction blanket

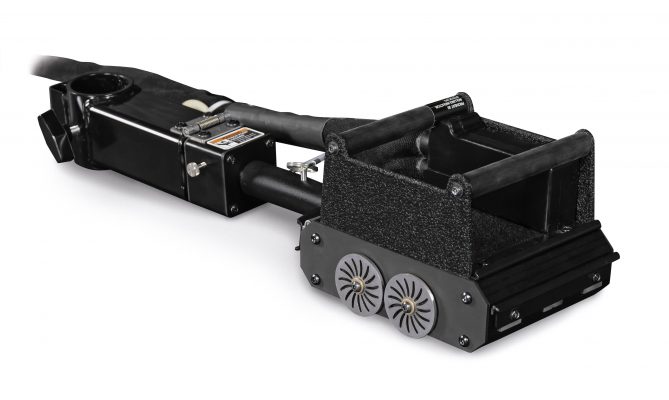

per-sized on pipes’ diameters - Rolling Inductor

For rotating or moving parts - ArcReachHeater

I will support you in adding the content, videos.

Say goodbye to unsafe, inefficient, less productive flame heating, resistance heating process and try the advanced, productive, quality induction heating process to experience the following advantages:-

Easy setup with a per-arranged simple fixture

- Reduce heating hazards

- Adding level of the friendly environment (no fumes, no heat losses…etc.)

- Generates heat inside base metal

- High hydrogen bake out efficiency

- No surface contamination’s

- Fast & controlled heat generation

- Temperature can be recorded

- Free space for a welder on the welding side